A thermal break is essentially an insulating material that is strategically placed within building envelope assemblies to mitigate heat transfer. Before diving into more details of thermal break, we first need to understand the terms "thermal bridge" and "continuous insulation".

What is a Thermal Bridge?

A thermal bridge is a conductive pathway through which heat can easily flow. Steel and concrete are common thermal bridge materials. A thermal bridge happens at a localized area. It creates higher thermal conductivity than the surrounding material and affects the overall building's energy efficiency.

Why does a Thermal Bridge Matter?

Those thermal bridges create a weak spot within a continuous insulation that allows heat to leak and leads to increased energy consumption, which results in higher utility bills and potential condensation and mold-growth.

Several problems might occur when a thermal bridge is present, such as a larger carbon footprint. Moisture issues related to condensation, mold, rust, and eventually rot. It also brings discomfort to building occupants and results in a higher energy bill.

How is the thermal bridge formed?

Thermal bridges are formed within structural assemblies through which heat passes through the insulation layer faster than in its surrounding area. The thermal bridge could happen at the location where protruding or recessed edge or junction elements meet. The odd geometry disrupts insulations and causes a thermal bridge.

Generally speaking, thermal bridges reduce the effective R-value by 50%; thus, improving thermal bridge condition would improve the energy performance of a building by 30% to 60%.

What is "transmittance"?

The term transmittance in the context of ASHRAE refers to the overall coefficient of heat transfer, also known as the U-factor. U value and R value are reciprocal of each other (U=1/R). They are both critical metrics to evaluate the energy efficiency of a building.

There are three types of transmittance:

Clear field transmittance: It means heat flow per area

Linear transmittance: It results in a linear form. It is usually wrapped around the entire building in several areas, such as cladding, shelf angles, balconies, or parapets.

Point transmittance: It is considered feasible on an individual basis for the sake of U-value calculation.

What is continuous insulation (CI)?

According to the definition from 2024 International Building Code, Continuous insulation refers " Insulating Material that is continuous across all structural members without thermal bridges other than fasteners and service openings. It is installed on the interior or exterior or is integral to any opaque surface of the building thermal envelope."

Why does continued insulation matter?

It helps reduce the energy consumption: Continuous insulation is a critical factor in the demand side when designing an HVAC system.

It is a code requirement: Continuous insulation has been part of various building component. For example, it is required to have continuous insulation entirely above the roof deck, at above grade walls or some area at the floors. (per 2024 IECC table C402.1.3 and 2024 IRC Table N1102.1.3)

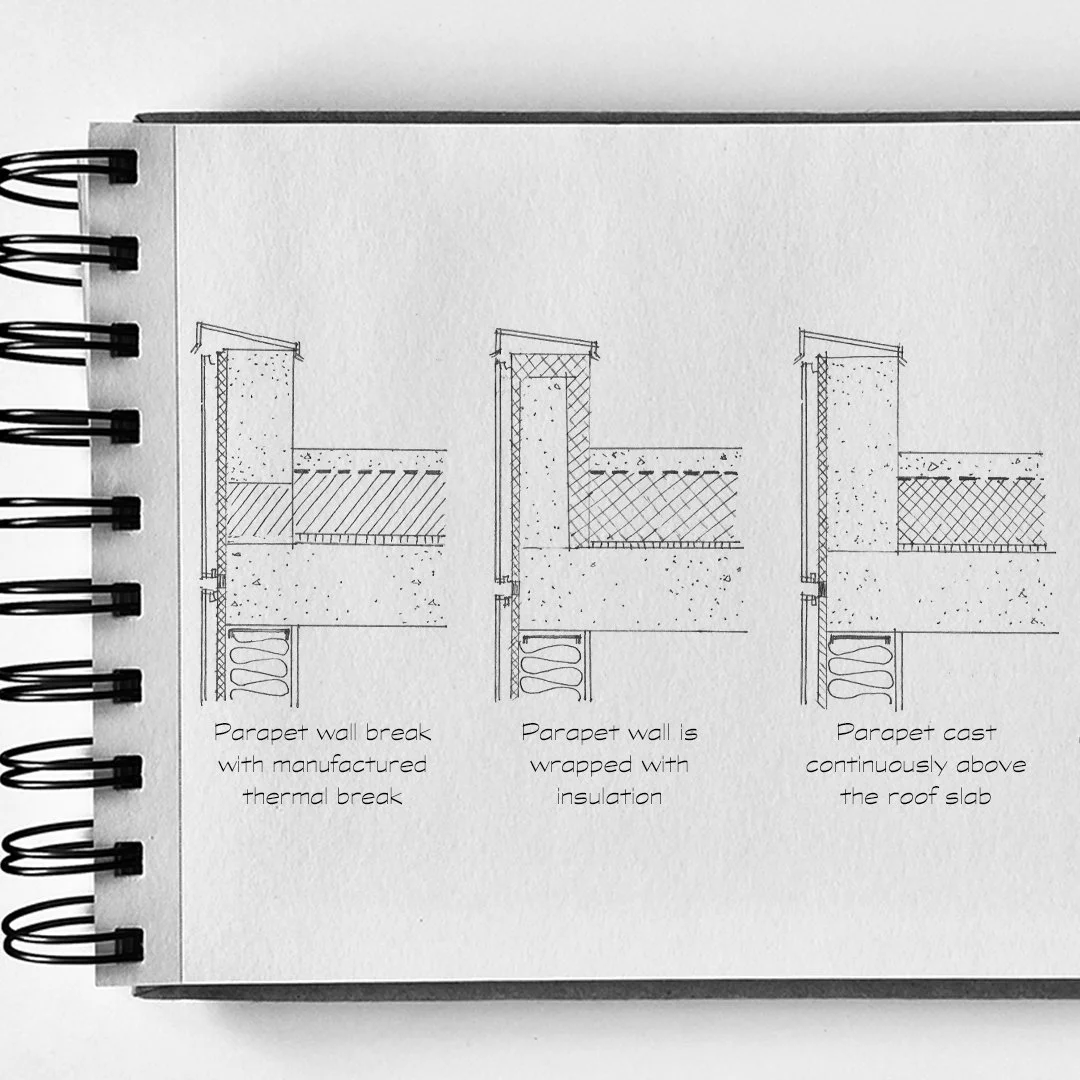

Parapet with thermal break has only 18% of heat loss, while parapet wrapped with insulation and parapet cast directly on the roof slab has 24% and 31% of heat loss respectively.

So, how can we design a thermal break to ensure there is a continuous insulation layer within the building envelope?

Identify the critical area: determine the specific location that has higher heat transfer.

Use 3D thermal modeling: This tool helps identify thermal bridge locations and helps design better assemblies to mitigate energy loss in transitions.

Choose appropriate materials: Choose materials with low conductivity, such as high-density foam, to create a thermal break.

Install correctly

Customized when needed. Customize thermal break based on the building's program, geometry, and occupants' comfort.