Why does ventilation matter?

Ventilation is the most important topic when optimizing indoor air quality. It is because good ventilation in the space removes harmful particles and uncomfortable humidity in the air. Industry standards and building codes recommend specific requirements, such as ventilation rates, occupant density, system types, exhaust locations, controls, and operations, to ensure the health and well-being of building occupants.

Ventilation matters if you plan to make your house LEED v4.1 certified

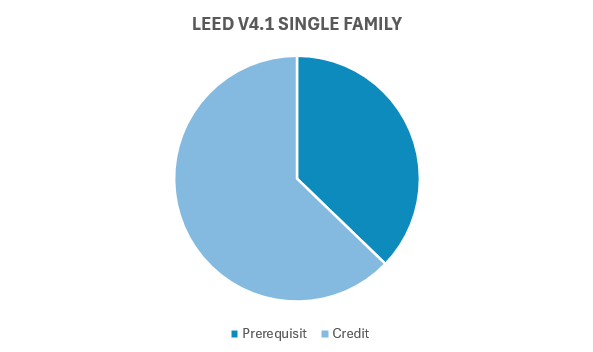

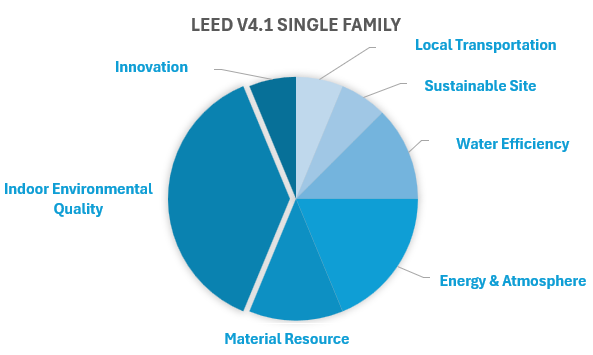

There are 16 prerequisites and 27 optional credits available for LEED single-family certification. In the LEED rating system, prerequisites are mandatory and must be met for the project to be LEED certified.

Among all categories, Indoor Environmental Quality covers 6 prerequisites, which are the most influential category. The ventilation is one of the prerequisites within this category.

What are the ventilation standards used for a single-family house?

The first and foremost is ASHRAE 62.2 "Ventilation and Acceptable Indoor Air Quality in Low-Rise Residential Buildings”. The standard provides recommendations for various aspects, including whole-building ventilation calculations, local exhaust selection, installation requirements, and suggestions for air-moving equipment.

The second is the International Residential Code (IRC). IRC chapter 15 was specific about the exhaust system related to dryers, domestic cooking, bathrooms, and whole-house ventilation systems. The code regulates exhaust discharge locations, protection of exhaust ducts, duct construction, duct length limits, and exhaust termination clearance.

P.S. The LEED v4.1-Single Family rating system uses ASHRAE62.2-2016 and IRC 2009 as reference standard. Due to the limited resources, this article uses ASHRAE 62.2-2013 and IRC 2021. You can refer to it at the link below.

What are the ventilation credit requirements in LEEDv4.1?

The requirements described in the LEED rating systems are:

Whole-house mechanical ventilation

Minimum Air Flow in the kitchen and bathroom

Whole-house ventilation means using one or more fans and duct systems to exhaust stale air and supply fresh air to the house. It is in contrast to the spot ventilation when planning HVAC systems for your home.

In addition to whole-house ventilation requirements, ASHRAE 62.2 recommends an intermittent or continuous ventilation rate for bathrooms and kitchens as alternatives to operable windows. It states 50 cfm at the bathroom location and 100 cfm at the kitchen ASHRAE 62.2 per Table 5.1.

What are HRV and ERV, and what’s the difference between them?

HRV stands for Heat Recovery Ventilator. It is a mechanical ventilation system that exchanges stale indoor air with fresh outdoor air while recovering heat and enhancing energy efficiency.

ERV stands for Energy Recovery Ventilator. Many people use it interchangeably with "Enthalpy Recovery Ventilator," which seems more suitable for the function of the equipment. ERV is also a mechanical equipment typically integrated into a building’s HVAC system, and admits the air stream to pass through the exchange core without direct mixing.

The difference between HRV and ERV is that HRV does not require the water vapor within the airstream to change its state, also known as the latent heat. Therefore, it does not remove moisture content in the air.

Using HRV/ERV in the home can effectively reduce energy consumption, which is beneficial if the project wants to achieve LEED's EA (Energy and Atmosphere) credit.

What's Next?

Other than following the steps to design your whole house ventilation system. Homeowners could spend some time reading the LEED rating system guide. Even though your home is not intended to get certification, following the requirements in the guide will ensure your house has the most sustainable outcome.

If you like this article, you might also like: “Ready for winter? Tips to save energy and money for your home.”

Notes and references:

ASHRAE 62.2 - 2013 “Ventilation and Acceptable Indoor Air Quality in Low-Rise Residential Buildings.”

The International Code Council (ICC) separates the code scope into the International Building Code and the International Residential Code for administrative purposes. The International Residential Code is written mainly for detached one and two-dwelling units and townhouses with less than three stories.

There are four main strategies in the whole-house ventilation system

Exhaust ventilation

Supply ventilation

Balanced ventilation

Balanced heat recovery ventilation

While the code does not limit the builder to which system to use. Exhaust-only systems are most applicable in cold climates because depressurization done by the exhaust can draw moist air into building wall cavities, where it may condense and cause moisture damage.

The supply ventilation systems, on the other hand, are most applicable in a hot or mixed climate. Because the pressurization done by the supply air may cause moisture problems, such as condensation, in cold climates.

A balanced ventilation system is designed to supply fresh air to bedrooms and living rooms where people spend the most time, and exhaust air from rooms where moisture and pollutants are generated, such as the kitchen, bathroom, and laundry room.

“Fact Sheet: Whole-House Ventilation Systems”, via Oak Ridge National Laboratory

“Guide to Home Ventilation”, via Department of Energy

“Evolution of ventilation from the basics to smart recovery and everything in between”, GreenHome Institute Youtube Channel